The constant drive for improvement in manufacturing and construction can often be a struggle, and this frustration can lead to issues that often hinder progress. Many of the organizations we have worked with over the years have felt that traditional methods had run their course, and they were failing to deliver the significant results required. But once they had been introduced to the Gemba walks process they could see firsthand how this deceptively simple practice helps to identify and address issues on the ground in a useful way.

Gemba is a Japanese term, and these organized walks offer an effective method to observe, engage, and potentially improve processes in the work area. Visiting and observing the workplace in this way can offer a fresh perspective and this hands-on approach can empower management teams to achieve continuous improvement.

What is a Gemba Walk?

The concept originates from Japan, where “Gemba” means the real place, so in this case, the actual work area, and “Walk” simply refers to physically visiting and observing the workplace in person rather than relying on second or third-hand reports. There truly is something special about being physically present at the sharp end and this has become a fundamental concept in modern continuous improvement approaches, emphasizing the importance of going to the source to identify opportunities for improvement.

Origins

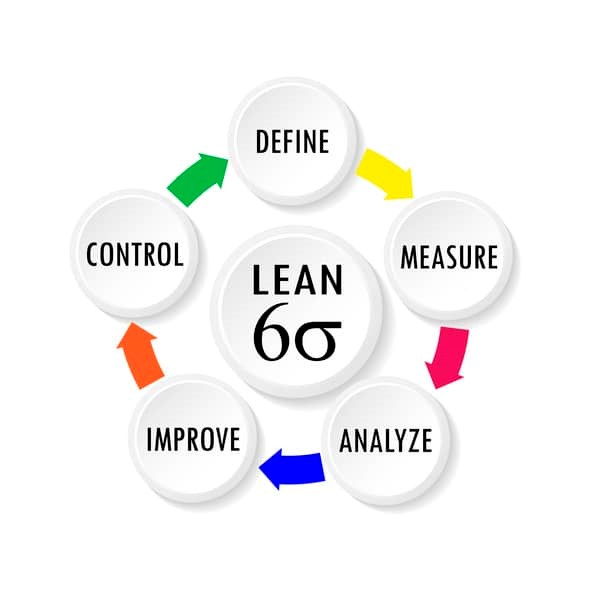

Gemba Walks were initially popularized by Taiichi Ohno, the father of the Toyota Production System. Ohno also pioneered other Lean Six Sigma practices and believed that managers should spend time on the shop floor observing the actual place where work happens. The huge success of this practice in the automobile industry has led to rapid adoption in lean manufacturing sectors and even the construction industry. Successful Gemba walks allow leaders in any sector to accurately identify inefficiencies or problems, allowing them to implement strategies for improvement.

Modern Applications

Gemba Walks have evolved far beyond car manufacturing and are widely used today in construction and other industrial sectors. But the purpose remains true to the original – to gain direct and valuable insights from the front line to assist in the development of a culture of continuous improvement.

A particularly valuable aspect of the process is that businesses can observe the areas where bottom-line value is created. This area of business is sometimes called the ‘value stream’ as this is the area that can account for most of the revenue. Whether it’s called the shop floor, factory floor, or just the front line, this is the area where an effective gemba walk can produce a fresh perspective that can pay dividends.

Over the years, our group communication systems have helped facilitate Gemba walks in a variety of noisy environments that make it difficult to ask questions and interact with team members and leadership. By using manufacturing tour headsets and construction headsets, businesses are able to turn the Gemba walk philosophy into a reality for their organizations.

The Purpose and Benefits of GEmba Walks

Key elements of a Gemba Walk

See the work – observe the work environment in real-time, up close, and in person. Gemba walks are not desk exercises and require leaders to be on the front line witnessing the work as it happens.

Listen and learn – engage with frontline workers to gain a fresh perspective and understanding of the operation. This offers a perfect opportunity for management to interact with team members and collaborate in the improvement process.

Respect the team – while the goal is to identify improvement opportunities to streamline processes, it’s critical to show respect and appreciation for the workers during the process. It’s not about analyzing their individual performance, but rather the challenges and opportunities for process improvement. This is a key part of the Gemba Walk and leaders should actively involve team members in discussions and encourage them to propose solutions as part of an iterative problem-solving process. This integrated approach helps to ensure continuous improvement over time.

The Gemba Walk Process

Gemba Walking is a process that can be broken down into several key steps:

Step 1:

Define the purpose and extent of the Gemba Walk by using clearly defined zones or processes to be observed.

Step 2:

Prepare a checklist or template to precisely guide the observations to enforce consistency and ensure all relevant information is captured.

Step 3:

Explain the objectives to the group and encourage participation by reassuring them that the goal is process improvement rather than assessing blame or finding fault.

Step 4:

Carry out the Gemba Walk by spending time in the work area and actively seeking insights and feedback from team members while observing work processes.

Step 5:

Document key findings and observations. Decide which processes need improvement and talk about implementing them with the group.

Step 6:

Collaborate with the crew to create plans to address any issues that have been identified. Assign clear responsibilities and set realistic goals for each team member.

Step 7:

Implement the action plans and review progress at regular intervals. Track key performance indicators (KPI) to evaluate the effects of the improvements.

Step 8:

Repeat the process often using regular gemba walks to maintain constant continuous improvement.

Incorporating Gemba Walks into Lean Management Practices

Gemba Walks emphasize going directly to the source to find opportunities for improvement. Organizations we have assisted over the years find that this aligns perfectly with the modern principles of lean management philosophy. The feedback we receive indicates that integrating Gemba Walks into daily operations helps to establish a culture where leaders and front-line staff collaborate to successfully drive continuous improvement in their daily operations.

What’s the Difference between Gemba Walking and Management by Walking Around (MBWA)?

When we initially discuss Gemba Walks with clients, they often respond initially by saying that they were already doing that and it’s just another version of Management by Walking Around. This assumption that the two are the same is very common and completely wrong. At best these techniques are superficially related but they are not comparable at all.

Different and much more specific goals

The goal of a Gemba Walk is to examine the current processes by observing them in action at the place they occur. The aim of a Gemba Walk is focused and very specific. Management by walking around (MBWA) involves seeing what’s going on in the workplace in much broader terms, often amounting to little more than management teams wandering around just saying hello.

Fixed destinations

A Gemba Walk happens in a predetermined area to observe a specific activity. With Gemba walking you always know ahead of time where you are going and what the focus will be. In management by walking around, the destination is not specific as this is a much less structured process by design.

Different approaches

During a Gemba Walk, in-depth and open-ended questions will be asked about the procedures being observed and a Gemba Walk checklist or template will be used. Whereas management by walking around usually involves more generic questions that are not specific to the process being observed.

Effectiveness

According to our clients, management by walking around is rarely effective. The reason is often that executives with no specific plan or destination have little idea about what useful questions to ask as they walk around. In addition, they typically will not pause long enough at any location to carry out detailed observations. Gemba walking on the other hand involves a fixed destination with a written plan or blueprint prepared in advance, resulting in real and measurable benefits.

Conclusion

Gemba Walks should be an essential aspect of any lean management philosophy. Though at first many of our clients needed some convincing to invest time and effort into Gemba Walking, they soon found that going directly to the source, the “genchi genbutsu”, proved to be a valuable tool for optimizing operational processes. The tangible results encouraged organizations to begin the process of fully integrating Gemba walks into daily operations.

Although Gemba Walks have been around since the early 1990’s, when paired with modern communication technology they still offer an ability to gain real-time insights and drive continuous improvement for our clients in manufacturing, construction, and related sectors. Incorporating Gemba Walks has helped to streamline business processes and identify root causes of problems, turbo-charging the improvement process.