On the production floor, machines and workers keep products rolling off the production line. But beneath the surface, the hidden force driving efficient production processes is effective communication. A staggering 86% of manufacturing employees blame workplace failures and frustrations on poor communication. Poor communication and messaging leads to a lack of collaboration, higher accident rates, more production problems and employee dissatisfaction.

In manufacturing, clear and efficient communication is the key to smooth running production lines and employee retention. This article will detail why effective communication is so important in manufacturing, explain the common barriers to efficient communication as experienced by many of our manufacturing clients, and provide practical ways to overcome these barriers and enhance communication.

Understanding the Importance of Effective Communication in Manufacturing

Effective communication is crucial in manufacturing and underpins operational excellence, safety, and innovation. Clear communication facilitates rapid problem-solving, which minimizes errors and accidents, while optimizing the allocation of resources. Effective communication improves all aspects of manufacturing, from production and supply chain management to employee engagement and customer satisfaction. Clear communication also enables manufacturers to implement new technologies and adapt to changing market conditions. Prioritizing good communication between all stakeholders creates a more productive and cohesive work environment. According to Gallup, companies with highly engaged employees are 21% more profitable, which can ultimately drive success in the modern competitive landscape.

Common Barriers to Effective Communication

Before we begin exploring potential solutions to poor communication practices, it’s important to recognize the challenges that can often hinder communication in manufacturing settings. According to our clients, the most common challenges are:

- Hierarchical management structures that impede the flow of information and discourage feedback.

- Lack of standardized communication methods and protocols across departments.

- Outdated or inefficient communication tools and technology.

- Shift work that can limit interaction between teams.

- Noisy work environments that make verbal communication difficult.

- Language barriers in workforces of diverse backgrounds.

Recognizing these barriers to communication is the first step in developing a robust strategy that addresses the unique communication needs of manufacturing employees.

8 Ways to Improve Communication

The following methods to improve communication are not ranked in any order, as the importance of each method will vary depending on individual circumstances. But all are included as they have been helpful to manufacturing companies we have worked with.

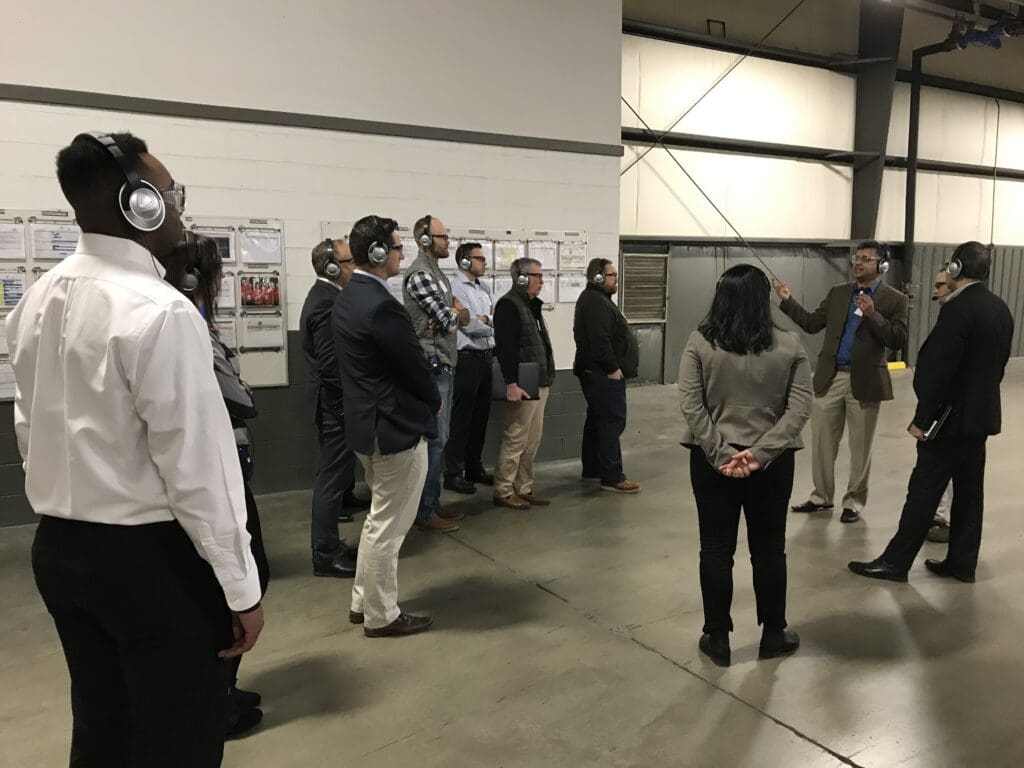

Implement Communication Tools and Technology

Clear and timely communication in manufacturing is essential. Implementing modern communication tools such as personal radios and noise cancelling headsets can significantly enhance the flow of information on the production floor by providing easy two-way communication. Mobile apps can also be useful, but two-way radios ensure reliable and clear communication and can be used even in areas with low cellular signal strength. Establishing basic rules of radio etiquette and protocols promoting the use of clear and concise language helps to avoid mistakes and unnecessary interruptions to production.

Comprehensive training in the use of two-way radios should be provided for all employees to cover all the essential communication requirements, particularly with regards to safety. Clear protocols should be established for health and safety practices and using two-way radios to quickly notify medical teams and coordinate responses. This training should form part of a crisis action plan to ensure employees are prepared for emergencies. Two-way radios allow frontline workers to stay connected, receive important updates in real time, and quickly report issues that may prevent costly delays and accidents, while improving overall manufacturing efficiency.

Establish Clear Communication Channels

Establishing clear communication channels in a manufacturing setting can significantly enhance productivity, efficiency, employee satisfaction, and safety. The provision of clear communication channels help foster connection and engagement among workers. Regular feedback and open dialogue between management and workers create a work environment where employees feel valued and part of the team.

Productivity on the factory floor is also improved when information flows smoothly, as workers can address problems and issues, allowing management to quickly implement solutions minimizing any production delays. In manufacturing, where safety is paramount, clear communication channels also enable efficient reporting of potential hazards or accidents, rapid dissemination of safety protocols and updates, and effective training on safety procedures and crisis management.

Prioritize Two-Way Communication

For communication to be effective in a manufacturing environment it has to be a two-way street. Communication is not simply disseminating information from the top down, it’s just as important that feedback from frontline employees on the factory floor is also encouraged. This two-way communication can be prioritized by fostering an open culture and providing apps and messaging platforms where employees can easily provide feedback.

Invest in Training and Development

Investing in communication training programs can enhance communication skills throughout the organization by focusing on active listening techniques clear and concise written and verbal communication, conflict resolution, and cross-cultural communication for diverse workforces. Equipping employees with these enhanced communication skills will not only improve everyday communication but can also help to develop future leaders within the company.

Leverage Visual Communication

Noise levels can be high in manufacturing environments so visual communication can be incredibly effective. Techniques such as color-coded systems for safety and inventory protocols, infographics and posters to communicate complex procedures, boards for tracking production goals and other business metrics, and video tutorials for training and manufacturing processes and safety procedures. Visual communication techniques transcend language barriers and high background noise levels to quickly convey important information on the factory floor.

Standardize Communication Protocols

One of the important aspects of effective communication is consistency. It’s important to develop and implement standard communication protocols and procedures across all departments. For example, reporting formats should be standardized for all production issues, terminology and abbreviations should be consistent throughout the organization, escalation procedures for complaints should be clear and accessible, and the formats and agenda for meetings should be uniform. Standardizing all elements of communication reduces confusion and ensures that all workers are on the same page regardless of their role or shift.

Embrace Technology for Remote Communication

With the increasing popularity of remote work and the reality of modern global supply chains, modern manufacturing companies need to adapt communication strategies to include off site workers and international partners. Technology can be utilized to bridge the distances involved by using:

- Video conferencing for meetings and training.

- Cloud-based collaboration tools for projects.

- Virtual reality for troubleshooting and maintenance.

- Wearable devices for real time monitoring and reporting.

These technologies allow seamless communication across distances to ensure that regardless of their physical location, all stakeholders remain engaged and are kept informed.

Foster a Culture of Open Communication

Cultivating an environment that encourages, and values feedback and open dialogue is crucial to improving communication. Employees providing helpful feedback should be recognized and rewarded while employees that voice concerns should feel safe to do so without fear of reprisal or recriminations. The importance of communication should be regularly reinforced, and management should lead by example.

The Benefits of Clear Communication on Safety, Employee Engagement and Compliance

Our clients report significant and tangible benefits thanks to the adoption of effective communication strategies. Common reported benefits include enhanced safety and reduction in accident rates, improved compliance with industry regulations, improved employee retention, boosted productivity, and better quality-control. In summary, every aspect of the entire manufacturing business is enhanced by improved communication. Effective communication seems to be a critical component of success in any manufacturing business. By implementing the eight strategies above, manufacturing companies can create a more connected, efficient, engaged, and productive workforce. Remember that improving communication is an ongoing process that requires consistency and long-term commitment. But over time, a profound and positive impact on profits, safety, and overall success is almost guaranteed.